A wiring schematic from your production line to your PLC is high recommended that way programming your Human Machine Interface is sped up drastically. Advantages The greatest advantage of a Human Machine Interface is that it is very user-friendly because of the graphical interface. CoDeSys allows for remote monitoring so you can see the status of your Programmable Logic Controller PLC or manufactuaring line from a remote location. Since CoDeSys is used worldwide it comes with a large amount of libraries specific to a device or general in functionality for all devices. How many different Human Machine Interface types do we offer and what are the major differences? Open Software is the last type, and this is for the advanced programmer. Oftentimes you may need constant feedback from your system, or printouts of the production reports, here is where the data handler is a perfect fit.

| Uploader: | Arabar |

| Date Added: | 4 January 2013 |

| File Size: | 34.62 Mb |

| Operating Systems: | Windows NT/2000/XP/2003/2003/7/8/10 MacOS 10/X |

| Downloads: | 95819 |

| Price: | Free* [*Free Regsitration Required] |

Human Machine Interface devices are innovative and capable of higher capacity and more interactive elaborate functions. A recipe word register is a klnco bit register that will execute sequentially when activated.

Human Machine Interfaces HMI's give you absolute control; meaning that you may give the user limited access to specific features or full access pending on how you create your interfaces.

Advantages The greatest advantage of a Human Machine Interface is that it is very user-friendly because of the graphical interface. The last of the three types is referred to as the overseer because it works with SCADA and MES softwaee are centralized systems which monitor and control entire sites or complexes of large systems spread out over large areas.

This is a very simple sanity check. The software required to program our Human Machine Interface differs from each vendor as well as model. How Does a Human Machine Kibco Work Let us begin with other components that are necessary to making a manufacturing control softdare operate.

Before the Human Machine Interface came into existence, there could be hundreds of pushbuttons and LEDs all performing different operations. Performing these tasks can be very memory intensive, so for the Human Machine Interface to work as a Data handler you have to greatly consider memory.

Anaheim Automation | Software Downloads

Before the Human Machine Interface came about controlling automation lines was no easy task due to the use of up to thousands of pushbuttons and LEDs all performing different tasks. Along with ease of access from wherever you may be, simplicity is also a big factor in the usability of a Human Machine Interface.

How to I download the software for the programmable logic controller?

What does Human Machine Interface stand for? With the data handler you must ensure your Human Machine Interface screen is big enough for such things: The graphical interface contains color coding that allows for easy identification red for trouble.

Easy Solution

Types Anaheim Automation offers three basic types of Human Machine Interface products which are the pushbutton replacer, data handler, and the overseer.

Description A Human Zoftware Interface Human Machine Interface is exactly what the name implies, it is simply a graphical interface that lets humans and machines interact.

Types There softwarw three basic types of Human Machine Interfaces: When it comes to selecting a Human Machine Interface, the physical properties are extremely important because you have to take into consideration the operating environment and what safety measure the Human Machine Interface has to protect itself. This HMI includes backlit keys, easily visible in the dark.

Components of a Human Machine Interface A Human Machine Interface is a big purchase so it is necessary to know exactly what it will be used for. Utilities uses the Human Machine Interface to monitor water distribution and wastewater treatment. How many controllers can Softwafe hook up to one Human Machine Interface?

Macro instructions is an advanced touch screen control method which strengthens the functions of the Human Machine Interface.

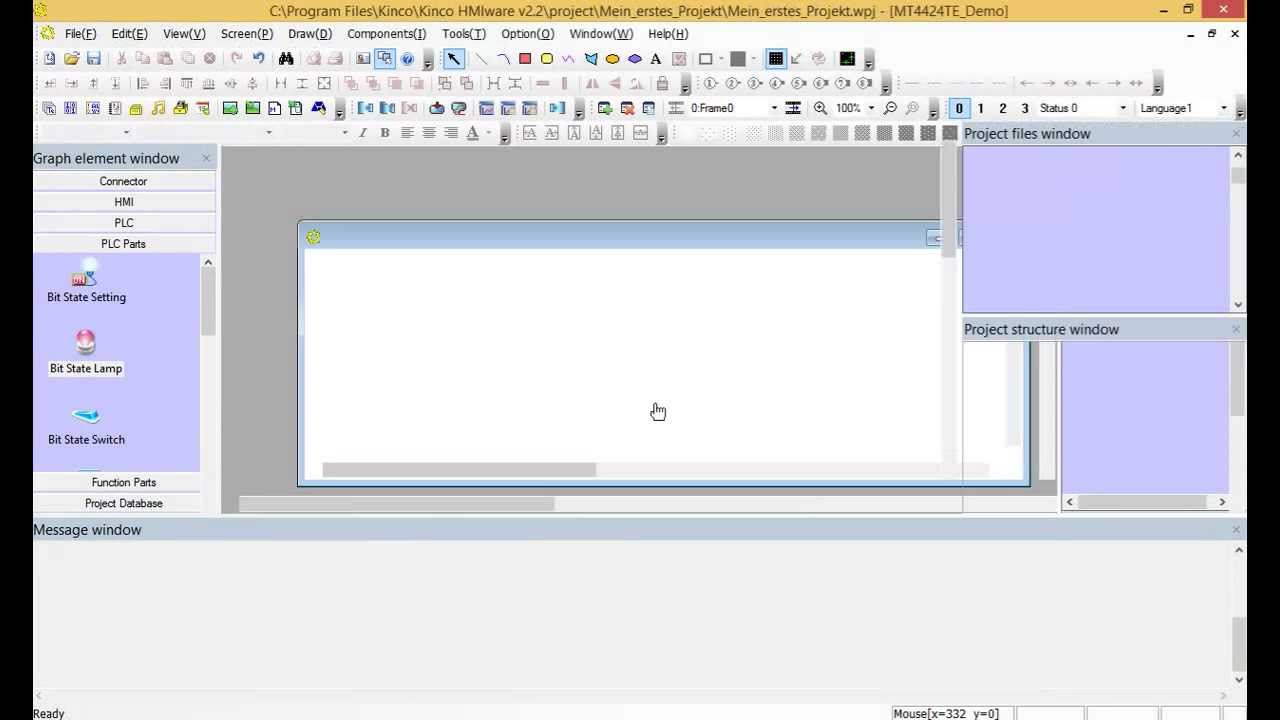

Kinco Automation

The use of macros will enable the touch screen to implement many powerful functions that cannot be supported by many regular components, perfecting your and to make your human-machine interfaces. Hanging or Rack Mounting. What programming language does the EV come standard with? A local word register is a 32 bit register which has been declared within the scope of the program. A wiring schematic from your production line to your PLC is ssoftware recommended that way programming your Human Machine Interface is sped up drastically.

What exactly did I do wrong? Lastly, physical properties include the processor and memory of the Human Machine Interface.

You may also want to consider temperature as a factor in your selection process because if you were to be in a steel plant and next to a furnace you would want something that oinco withstand those temperatures. That knowledge will transfer over when you are ready to connect the two units together. Featuring super-large storage space for user configurations, MT models can perform on-site data collection, processing and monitoring and can output data in a quick, effective, and secure manner.

The MT series supports online simulation and macros that are compatible with standard C language.

No comments:

Post a Comment