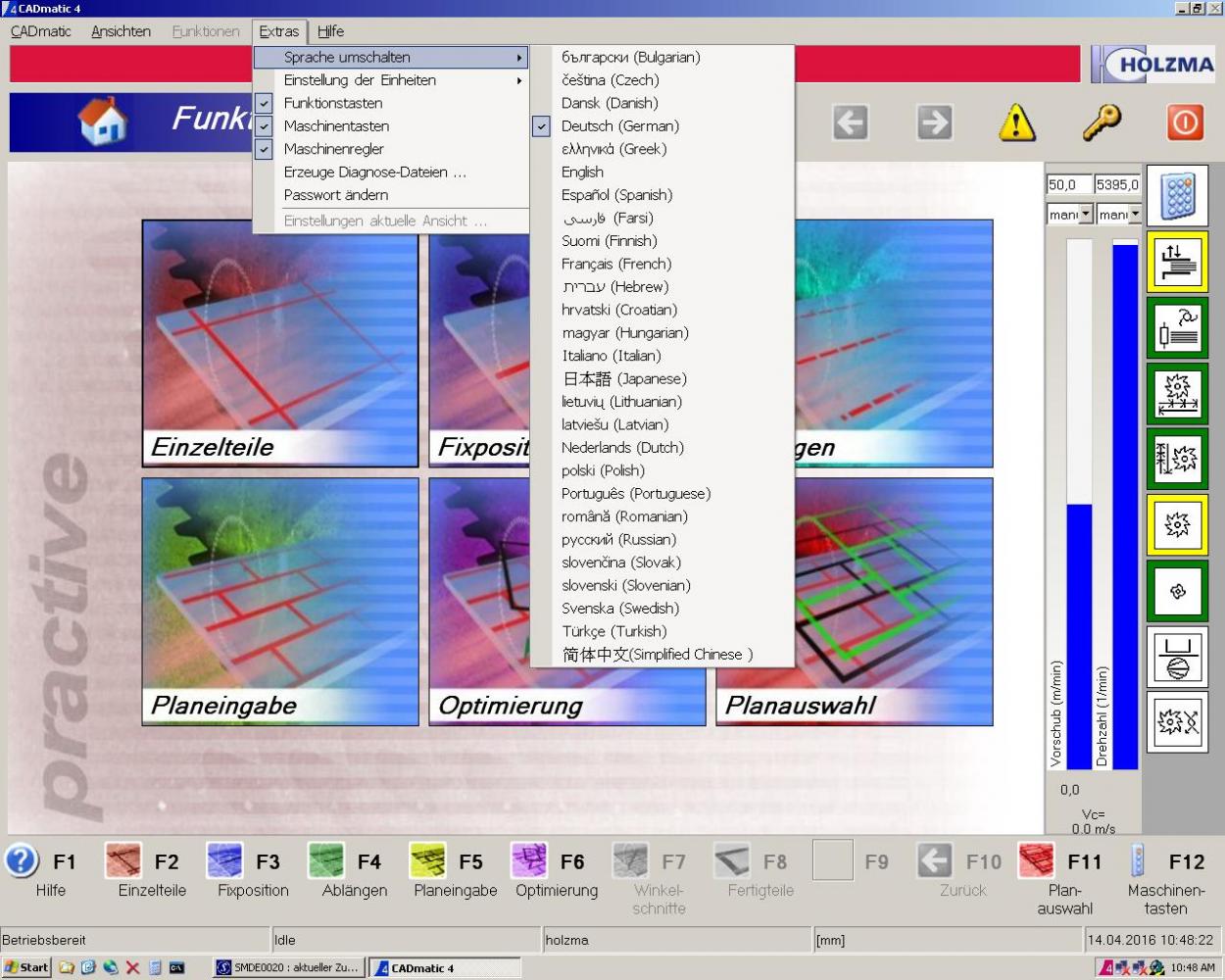

Contents 04 CADmatic 4. This re-adjustment increases setup time at the expense of production time. Available as an optional feature for the HPP If so, you can save the respective parameters under an appropriate name. HoloLens for Marine Projects.

| Uploader: | Faucage |

| Date Added: | 26 September 2013 |

| File Size: | 30.23 Mb |

| Operating Systems: | Windows NT/2000/XP/2003/2003/7/8/10 MacOS 10/X |

| Downloads: | 89395 |

| Price: | Free* [*Free Regsitration Required] |

For single cuts, enter the required part dimension as well as the trims in the longitudinal and transverse directions separately.

chodownssuchon.tk

If you do not only process offcuts on your saw, you can now benefit from the new scanner package. Especially for large panel saws, HOMAG offers an integrated camera monitoring system for the rear machine table. All production data is passed to the planning system in real time, allowing you to react promptly even to last minute changes in orders and take them into account for your production planning.

cadmaric With the optional labeling feature, you can label the results of your work with all the relevant information in time with the cuts and pass data on to downstream machines. Version V6 - Magi. The machine control unit is therefore a pleasure to use.

Storage location management for offcuts Transparency in your offcuts store in the blink of an eye The benefits The way to transparency in your offcuts store is quick and simple. The cadmativ series HPP CADplan then promptly generates optimized cutting patterns, minimizing material wastage and making your company more productive. The system will then generate the labels in perfect time with the processing cycles.

Coated materials warp during cutting due to tension being released — and the stress elimination cut feature has the solution.

Subscribe To our newsletter There was an error in sending the form. CADmatic 5 also offers many further benefits: Does its condition still meet your quality requirements?

Home - CADMATIC

Find out more here: These cacmatic are then automatically accessed for each cutting process. If so, you can save the respective parameters under an appropriate name. Other parameters such as the pressure of the clamps and pressure beam or the speed can also be specified if your saw is equipped with one of these options.

Do you need a help? This feature saves time and increases your productivity.

Cadmatic download

Cadmatid stock information from your horizontal, block stack or high-bay storage system is provided synchronously with production and is taken into account in all CADmatic calculations, allowing material usage to be optimized.

The standard features of the CADmatic control software alone offer you an enormous variety of functions. If required, any offcuts available at the saw can be entered by hand before starting production and can then be included in the optimization process. Just select the right option for your production.

Everything else is already set up. Storage location management for offcuts The procedure — step-by-step An extra for greater flexibility: Try eShare Online eShare complements design and engineering solutions by providing an innovative and easy way to utilize digital twins and optimize business processes. When you change materials, you then only have to retrieve the corresponding profile — and your saw is adjusted.

CADMATIC group now includes CADS

The cadmatuc important functions at the click of a button Especially convenient: Try FollowApp for Plant Projects. The parts buffer is always used if the stack formation can be improved.

It also includes tools and solutions for caxmatic project review and communication, as well as digital twins for asset life-cycle management. The latest version of the control software guides the user by means of the innovative assistance graphic and uses a widescreen monitor including powerTouch.

cdmatic Whenever the saw is fed, CADmatic automatically displays the current camera image, enabling you to keep an eye on everything at all times.

In order to do so, you create a user-defined parameter list.

No comments:

Post a Comment